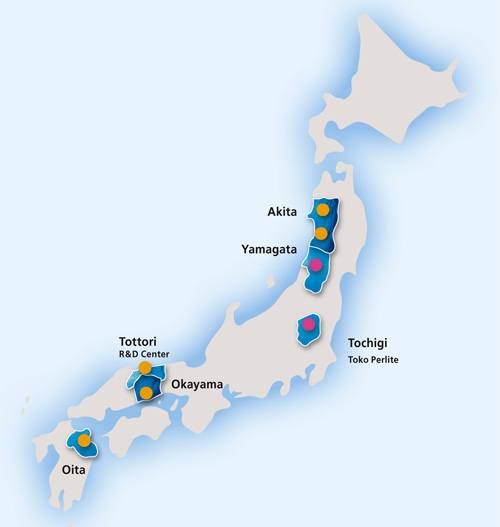

HomeOur Business Locations & Networks | Japan

Located in Akita prefecture in northeast Japan, the Akita plant is the only marine diatomite plant operating in Asia. One notable characteristic of diatomite found in Akita is its especially fine particle size, which is suitable for producting calcined filter aids for high clarity to flux-calcined filter aids for highspeed filtration, and filler use for use in silicone rubber manufacturing. The Akita Plant acquired ISO9001 as part of efforts to ensure consistent quality for customers.

The Oita plant, located on Kyushu Island manufactures both Radiolite® filter aids and filler products from 500,000-years-old freshwater diatomite. Fillers produced in Oita have a high degree of whiteness. Our filler, have found wide range applications for the manufacture of paper, rubber, plastic, dental impression materials, and paint. Oita plant acquired ISO9001 as part of our efforts to ensure consistent quality for our customers.

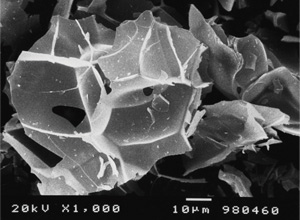

The Okayama plant, located on the main Honshu Island, was the first plant established by Showa having started production in 1933. It is also the largest diatomite production facility in Japan. In Okayama, Radiolite® products are manufactured from 100,000-year-old freshwater diatomite, which provides an extremely complex and highly porous geometry, and low density compared to other diatomite available in the world. With some particles as large as 100µm, and low density Okayama products are suitable for a wide variety of applications, from high-speed filtration to heat resistance or heat retention. Okayama plant acquired ISO9001 as part of our efforts to ensure consistent quality for our customers.

Tochigi plant

The Tochigi plant was established in 1965 as Toko Perlite to manufacture perlite for Showa Chemical Industry. In 2016, Toko Perlite was absorbed and merged to become the Tochigi Plant of Showa Chemical Industry, and is home today to the Topco® brand of perlite filter aids. When heated, moisture trapped inside natural perlite vaporizes and escapes, causing the perlite to expand into a popcorn-like structure, which is then sorted and ground into a powder-like form that is used for the manufacture of filter aids. Tochigi plant products come in a wide range of densities, from 0.04 to 0.30 g/cm3 depending upon the application, and demonstrate absorption and insulation properties combined with other stable physiochemical characteristics that make it suitable for use not only in filter aids but also filler for construction materials, soil conditioners, hand cleansers, filler, and heat insulation. Tochigi plant was certified ISO9001 as part of our efforts to ensure consistent quality for our customers.